Quality & Services

Product Sourcing is the basis of each and every order and proceedings. If our sourcing is from an appropriate source, the end product would also be as per our aspirations. We have strong roots penetrated all over for effective sourcing, covering all the product categories for all segments of international market.

The product development becomes active once the buyer has approved on our sourced products which are sent trough photo presentations. Products is developed according to buyer's requirements and dispatched within the date stipulated by the buyer.

All the samples are checked before sending so that the modifications, if any, are taken care of. We put tag with feeding all important data required by the buyer and keeps a counter sample in their record for all follow-up. The dispatch details are advised thereafter.

Merchandising

This involves entire execution of order from the initial to final stage, till the shipment is on board with massive and close follow up at various stages of production and updating buyer accordingly. Apart from this we take care of the entire packaging to be followed for a particular order. Normally we prefer to make it uniform for all the orders and standardize same so that it is approved once and for all and becomes easier for buyer too.

Factory Evaluation

Factory Audits / Evaluations are conducted to check the production capacity and the infrastructure of the chosen vendors. This audit is increasingly becoming important in the Indian context due to the linked problem of child labour, social welfare norms, pollution problems etc. The evaluation of the supplier's factory plays a vital role in contributing to the end product. We make sure that the factory has adequate resources and man power to complete the production and meet with buyer's quality standards. Thorough Audits are conducted by private auditors and Globus professionals to foresee the supplier's strength, the facilities being provided to their employees so that they work in full swing and in turn the merchandise meet the Delivery date etc.

Quality Control

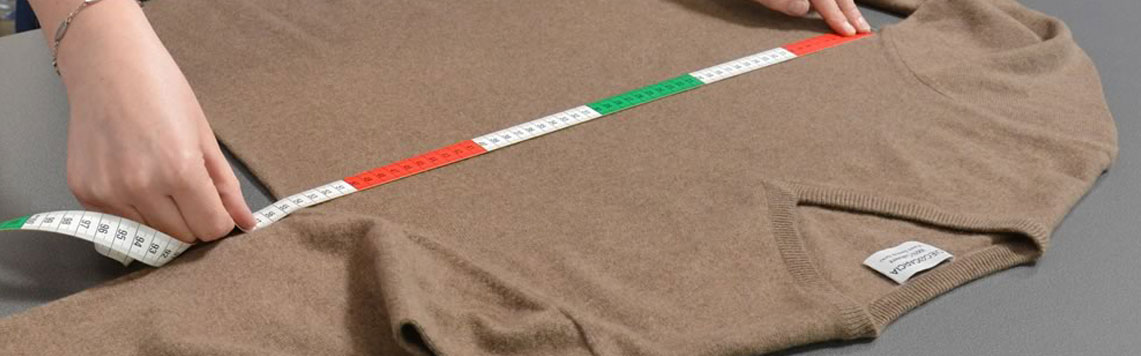

To be able to quality control the merchandise produced by its vendors, Globus Apparel Art has adopted the universally acclaimed system of quality evaluation known as the AQL (Accepted Quality Level). This system helps judge the quality level of the produced goods by identifying and categorizing the defects. It enables the QC to decide if the merchandise passes the acceptability norms of the client. We believe that quality control exercise must be simultaneous to production and is not a terminal exercise for this reason we monitor the quality at each stage of production in all respects. Above all we cannot control quality but can render our services to assure best quality.

Quality Process

Quality is our priority. We work as per the requirements and specification from our valuable clients. Our group of experienced professionals conducts rigorous quality checks at every stage of production and also after the final product is made the entire consignment is checked and timely dispatched. The process of Quality assurance follows as:

Selection of the vendor

Some of the prerequisites that we look for in our vendor are technical abilities, factory layout, equipments, personnel, productivity, financial strength and reputation, based on years of experience & interaction. If our client prefers a particular vendor, we work with them as well.

Briefing the vendor

A correct and unambiguous briefing is essential for a "first time right" product. Our expert and cognizant team members interact on a "one to one" basis with the vendors to give them a product briefing and explain the details related to raw material, dimensions, designing, process to be used etc.

Prototype and sample production

The production of the ordered lot starts only once the sample produced by the vendor is up to the mark.

In-house quality check, at our end

Our quality controllers ensure that quality is maintained throughout production process. The sample is sent to us for due verification.

Client's approval

Once the product satisfies us, we send it to the client for their final approval. If any modification is needed, we again send it back to the vendor and all the changes are carried out to meet the exact specification.

Mass production starts,

After approval, the production starts on a fully fledged scale. In order to keep a check, it will start with Inline production.

Visit from our personnel

At this step, again we do a quality check. This is done not only to ensure the quality of finished product, but also considers the warehousing conditions. The place must be spacious and fit for storing the end goods.

Further production completed

After the process and product is found out to be up to the mark, we allow vendor to further production and the entire consignment is produced.

Entire consignment checked, one more time

After the completion of the manufacturing process, the product is thoroughly checked. While the goods are being packaged, quality controllers re-inspect randomly, selecting packages from the final shipment.

Packed and dispatched

We ensure on-time deliveries to our clients. The packaging ensures minimal loss during transit and ease in unloading. If client needs a special packaging, we do arrange it. All the shipping and documentation are also coordinated by us to reduce the workload of our client.

Logistics

Only after receipt the "OK for shipment" from Globus Apparel Art, the supplier is permitted to dispatch the goods.

The Logistic Department follows up the shipment once he gets the "OK for shipment" from the QC Department. He is in regular touch (several times a day) with the clearing and forwarding agent and gets a daily report by fax in order to follow-up the documents required for shipping and to monitor closely the movement of cargo. This ensures that it is put aboard the targeted vessel and meets the deadline of the buyer. A special software has been designed to enable a proper follow-up. We also take proper care of the consolidation of merchandise, as buyer normally prefer to have the merchandise consolidated from various suppliers.

The Logistic Department makes sure that all the documents required for import are sent to the buyer in order to avoid delay in clearance of goods at destination. Globus Apparel Art finally sends a shipping advice with all relevant details of shipment.

Globus Apparel Art is actually an "extension" of his client and assists him from the very initial stages to the final shipment. It takes the burden of all the follow-up action on behalf of his client and ensures a smooth "sailing".